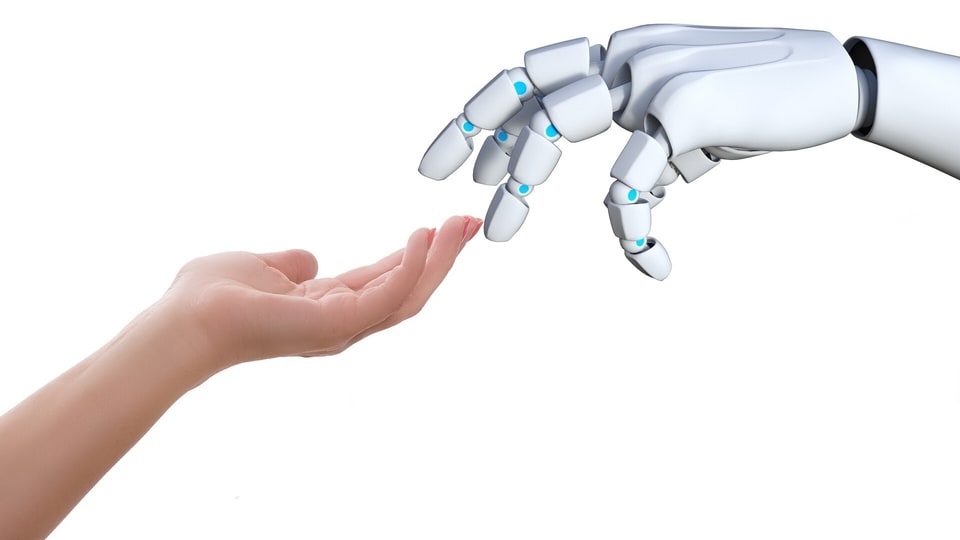

Industry 5.0: Exploring the relationship between humans and machines

With Industry 5.0, the complementary relationship between humans and machines will be reinforced to create better outcomes for all.

Innovations in the last decade are proof that we have progressed in many ways by leveraging technology to its fullest potential. Among the many phases of innovation, Industry 4.0, or the fourth industrial revolution, has been one of the most powerful concepts that has enabled organisations to digitally converge across industries, businesses, internal functions and manufacturing processes. To highlight one of many benefits of Industry 4.0, manufacturers for example, have benefited from proactive maintenance and better tracking and usage of their equipment - ensuring uptime availability and smooth running of critical operations and processes.

For instance, one of the world's largest two-wheeler manufacturers has benefitted from customised tech solutions. Facing extensive downtime and lost business due to legacy infrastructure, the adoption of hyper-converged infrastructure provided scalability, reliability, flexibility, and security, allowing them to improve quality and production, and focus on serving their customers better.

The human element in industrial revolution

But while Industry 4.0 promised an unprecedented era of automation to improve operational efficiencies, the collaboration between machines and humans remained limited. We simply relied on the technologies to do their job while we did ours/ For example, tech-powered sensors helped predict the probability of machines failing, and humans would then address these issues through predictive maintenance.

However, to go one step further and provide cognitive support - identifying root causes of technical problems and achieving wider organisational goals, human comprehension of different variables is still required. Technology may play an important role, but human knowledge and expertise continues to be critical. Although machines can process much larger volumes of data than humans and also easily uncover patterns that would otherwise go undetected, determining business priorities and connecting the dots is something only people can do.

With Industry 5.0, the complementary relationship between humans and machines will be reinforced to create better outcomes for all.

Collaboration between humans and machines

Organisations recognise that data is the new currency amidst today's digitally driven landscape. And that beyond the numbers, it's people who will continue driving the world. Being data-centered is key to better serve customers' needs today and in the future. By progressing from ‘man vs machines' to ‘man and machines', the potential of this symbiotic and complementary existence is limitless. In fact, an EY survey reveals 66% of manufacturing firms in India rank big data and predictive analytics as their top investment priority in tech. In this data-driven market, manufacturers who can distill actionable insights will be better positioned to gain competitive advantage - be it visualising key performance indicators or improving industrial operations.

We've already begun to see even greater personalisation and enhanced customer experience with the start of Industry 5.0. Enabling co-creation, manufacturers can work hand-in-hand with customers to design products that meet their needs. In fact, the popular Italian car manufacturer, Ferrari, already has a personalisation program called ‘Build your own Ferrari', offering a range of customisation options for customers to tailor-make every last detail of their car. In other industries like beauty, experts are also customising skincare treatments for individual patients with the help of technology. If one explores different use cases across different industries, the sky is truly the limit!

As we welcome the future of even more technology-driven innovation, the need for human intervention will likely be reduced. However, with this advent of ever-advancing solutions, overall value creation is poised to increase, and outcomes will improve. As we make progress in enabling the data-centered—the businesses and people who leverage data to better cater to their customers—the future of manufacturing is exciting and will be filled with unparalleled creativity. From automation to innovation, or even smarter technology, businesses can surely look forward to enhancing productivity, increasing profitability, and improving performance, helping their organisations scale new heights.

This article has been written by Vivek Sharma, MD, India, Lenovo ISG

Catch all the Latest Tech News, Mobile News, Laptop News, Gaming news, Wearables News , How To News, also keep up with us on Whatsapp channel,Twitter, Facebook, Google News, and Instagram. For our latest videos, subscribe to our YouTube channel.