Industrial robots are going to lead the Atmanirbhar Bharat dream

While these machines are getting smarter, manpower is still needed to work around them to operate, monitor, and synchronise in many processes.

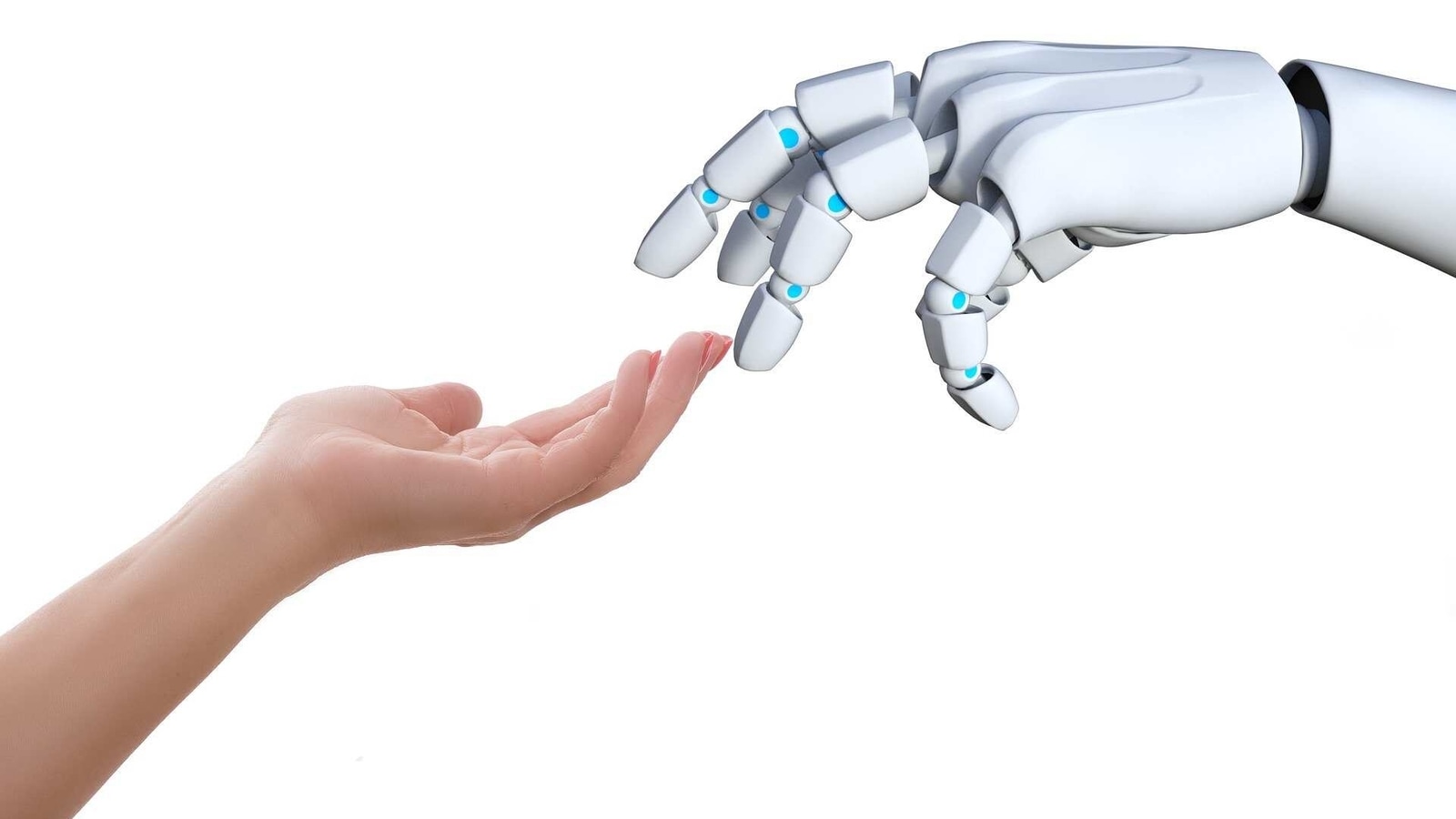

Robots have revolutionised the way people used to look at their processes. Traditionally in the 20th Century, robots were nothing but a big machine with automation, but in the 21st century, robots are used in a varied series of applications, from healthcare to outer space. Industrial robot technology is gaining momentum like never before, and it has evolved to new concepts of man and machine co-existence.

For achieving maximum efficiency, safety, and competitive advantage in the market, robot-driven automated manufacturing is becoming a norm. These industrial robots help in doing hazardous and repetitive tasks which ensures that the manpower on shopfloors is safe and can operate and synchronise with machines, thereby delivering precise, consistent, and efficient output.

There are numerous ways in which a robot can be used for industrialisation purposes. Categorised differently according to industries and applications, these robots vary in volume, process, accuracy, and flexibility. They have real solutions to help people with more complex tasks like welding, painting, lifting, moving heavy items, and high-precision pick and place applications.

The first phase of this revolution brought electric machines that performed repetitive tasks without fatigue. These robots were used in the automobile industry and other similar applications. The second phase brought industrial robots that besides performing basic tasks also absorbed data to evolve and become better.

There are a lot of myths revolving around industrial robots. One amongst them is that, with the penetration of robots in industries, humans will tend to lose their jobs. However, this isn't the case. Having said that, people need to understand the fact that humans can never become completely redundant as these robots may be very efficient but are still limited in numerous ways.

While these machines are getting smarter, manpower is still needed to work around them to operate, monitor, and synchronise in many processes. We humans need to spend more productive time in planning and doing smart work, while the robots continue to work on repetitive and fatigue jobs.

Nowadays, with the technology getting upgraded day by day, we have a new industrial robot, a new game-changer in this space - collaborative robot, popularly known as ‘cobot'. Simpler, easier, and flexible to use, cobots are designed to be a workspace partner. They are safe, require minimal or no programming, and allow hassle-free connectivity, which makes it an excellent option for a wide range of applications.

Collaborative robots like MELFA ASSISTA have a wide range of uses, including how to handle the components, assembly jobs offer a variety of finishes, apply sealant or glue, and a lot more. They are used in load building (at a production line's end, they assemble a pallet load of products), quality control (inspection and testing procedure involves the deployment of robots for repetitive work), transportation (load pallets before shipping), and warehousing (for carrying out the removal of received products from pallets and then route them to a facility's storage location). In addition to this, they are also widely used in Food and Pharma industry for handling pick-an-place jobs.

MELFA FR series industrial robots comes with robot control, it is a combination of all the technologies required to control an industrial robot's electromechanical system. A Programmable Automation Controller (PAC), Programmable Logic Controller (PLC), Embedded Controller, PC, Industrial PC (IPC), or Motion Controller can be used for robot control. The industrial robot allows various benefits, including gentle product handling, accuracy, quiet operation, improved efficiency, and flexibility.

Some robots may need programming, while others do not require any programming at all. For instance, MELFA ASSISTA can be programmed using a tablet, with simple point teaching. You just need to teach the moving points to ASSISTA, and your work is done. User can simulate the movement before actual transferring it to a cobot for confirmations. Alternately user can hand guide ASSISTA to the points and can directly teach with teaching panel available on cobot arm, eliminating the need for any complex programming and software.

Industrial robots are the future of Indian manufacturing, where factories will have zero labour fatigues, zero accidents, and improved quality and productivity with the help of an efficient synchronisation between man and machine. If used in a proper way with complete shop-floor data integration, this technology can put India on the world map of manufacturing and establish India as a manufacturing hub for the world.

This article has been written by Atul Patil, Assistant General Manager, Marketing Department, Factory Automation and Industrial Division of Mitsubishi Electric India.

Catch all the Latest Tech News, Mobile News, Laptop News, Gaming news, Wearables News , How To News, also keep up with us on Whatsapp channel,Twitter, Facebook, Google News, and Instagram. For our latest videos, subscribe to our YouTube channel.