From Sony Playstations, Toyotas to Teslas, China Lockdowns Upend Global Supply Chains

Automakers from Toyota to Tesla are facing “unprecedented” costs and production hurdles. Sony is struggling to make enough PlayStations.

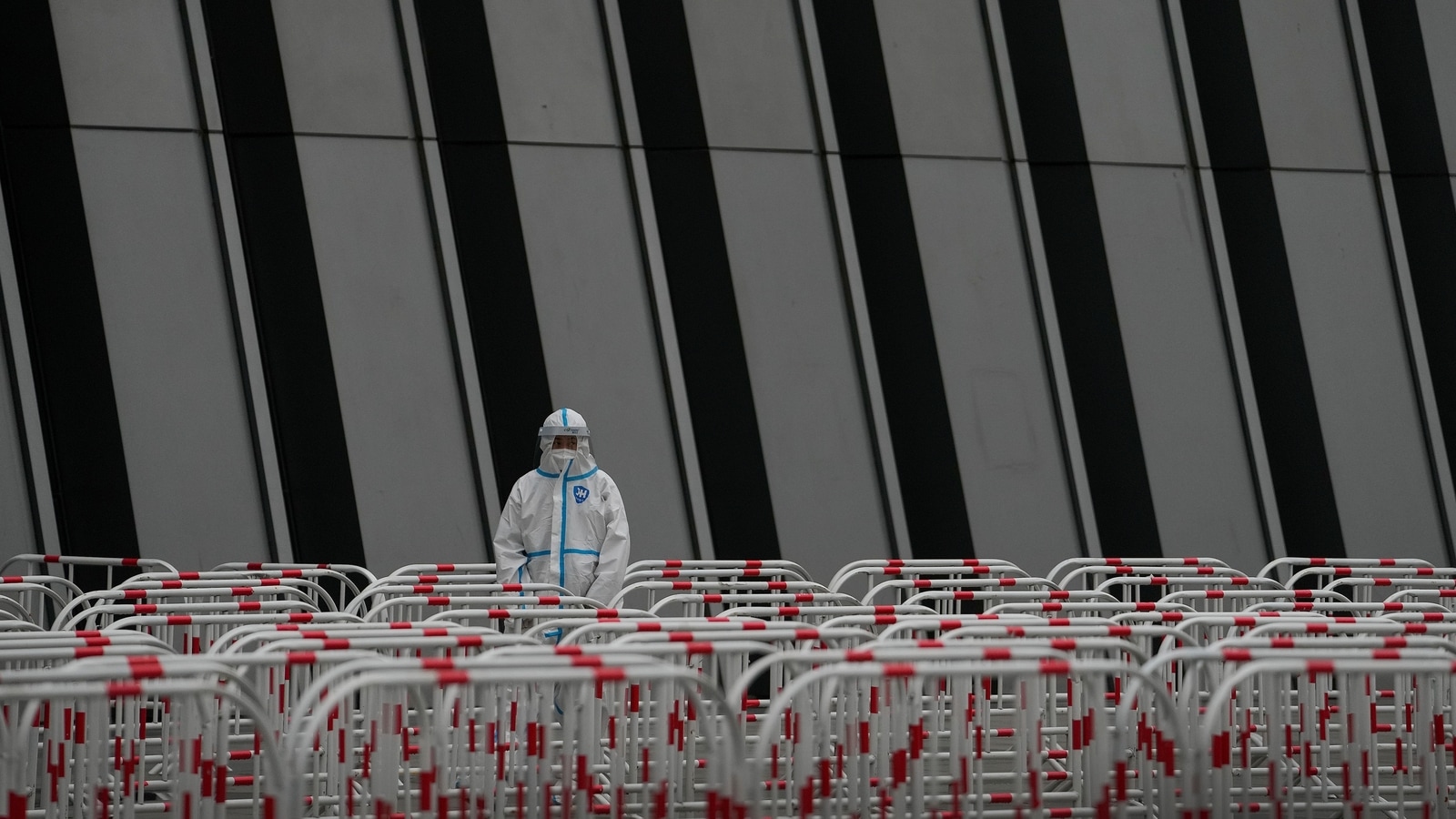

The economic consequences from China's Covid-19 lockdowns are starting to be felt by companies and consumers across the globe, and expectations are that the reverberations will only get stronger.

Supplies of Adidas sneakers and Bang & Olufsen speakers have been hit. Automakers from Toyota to Tesla are facing “unprecedented” costs and production hurdles. Sony is struggling to make enough PlayStations.

While “supply-chain disruption” is emerging once more as the most repeated phrase of corporate earnings season, the impact goes beyond multinationals' profits. Hospitals from the US to Australia are wrestling with a shortage of chemicals used in X-rays, while real-estate projects are held up by delayed materials.

Jake Phipps, whose US firm supplies luxury bathroom fixtures and kitchen countertops to skyscraper projects, is seeing months of delays for the shipment of faucets from Shanghai. “All the construction projects here are backed up waiting on raw materials,” he said. “The supply chain has been a mess already, and this is making it worse.”

Beijing's zero-tolerance approach to Covid has idled factories and warehouses, slowed truck deliveries and worsened container logjams. As the country accounts for about 12% of global trade, it was only a matter of time before the upheaval began to trickle across economies, threatening to further stoke rising inflation.

Global Supply Chain Crisis Flares Up Again Where It All Began

While the impact so far doesn't appear severe, this is likely only the beginning. The full significance of China's Covid restrictions has yet to be seen as lockdowns continue in Shanghai and other cities shut to contain smaller outbreaks, adding to supply-chain congestion that's already reeling from the war in Ukraine.

“Once Shanghai opens up again and everything is back into rotation, and you see all the vessels heading towards the US, that can pose additional challenges with additional congestion,” said Jonathan Gold, vice president of supply chain and customs policy for the National Retail Federation in Washington.

Here's how the situation in China is intensifying global supply-chain chaos:

Construction Projects

Phipps, founder of Phipps International, is growing more frustrated as his shipments of faucets have been delayed by two to three months, with no certainty of when they can leave Shanghai. Suppliers repeatedly told him “five more days,” and that has now stretched to 40 days.

One factory making the moulds to cast the faucets managed to start up last week after more than a month of inactivity. But the faucets, once made, still need to be moved to other factories to get chrome-plated and polished, and some of those plants are still shut. Then there's the dearth of truckers.

“That's one of the biggest issues - truckers aren't moving goods because the government doesn't want them spreading Covid from city to city,” Phipps said in an interview from Miami.

The wait for bathroom taps and other furniture to arrive from China will further delay construction projects in the US, some of which are already a year behind schedule, Phipps said. He is shifting some production from China to Vietnam and is buying marble, quartz and granite from Italy, Brazil and Turkey instead of China.

Sneakers & Apparel

Clothing and shoe factories in Vietnam are struggling to meet orders as supplies of Chinese material used to make everything from sneakers to pants are drying up.

The Southeast Asian nation is the second-largest supplier of clothes and shoes to the U.S., according to the American Apparel & Footwear Association, which represents more than 1,000 brands.

China's Covid Zero strategy is “dramatically” reducing key material at shoe factories, which derive about 60% of supplies from China, said Phan Thi Thanh Xuan, vice chairwoman of the Vietnam Leather Footwear and Handbag Association. Adidas SE this month cut its profit targets, saying supply bottlenecks in Vietnam have reduced the availability of products, eroding sales.

Technology & Games

The eastern Chinese region around Shanghai is a key center for tech production, and component shortages are hitting companies across the board.

Giants from Microsoft Corp. to Texas Instruments Inc. have said the lockdowns will crimp sales and make it harder to produce products like the Xbox. Apple Inc. said last month that the restrictions will take a toll on its June results, with supply constraints costing $4 billion to $8 billion in revenue.

Major iPhone supplier Pegatron Corp. this week cut its second-quarter outlook for notebook shipments. Semiconductor Manufacturing International Corp., China's biggest chipmaker, said the lockdowns could erase about 5% of its output in the latest quarter.

Top China Chipmaker, Apple Suppliers Succumb to Covid Lockdowns

Sony Group Corp., meanwhile, lowered its sales target for the flagship PlayStation 5, citing supply-chain complications because of the Covid-19 pandemic, including the lockdowns in China. Nintendo Co. also said there had been some impact on sales because of the situation in Shanghai.

Medical Supplies

Shanghai's Covid-19 curbs are even having an impact on health care, as lockdowns have sparked a global shortage of chemicals used in imaging tests.

Health-care facilities have seen shortages of an iodinated contrast medium known as Omnipaque that's produced at a GE Healthcare factory in Shanghai, the Greater New York Hospital Association said earlier this month. The chemical agent is widely used in X-rays, radiography and CT scans. The hospital body warned that supplies may be curtailed by as much as 80% for the next two months, even though the factory has now resumed production.

A spokeswoman for the Australian Society of Medical Imaging and Radiation Therapy said the shortage of the contrast dye could continue for weeks, and it may be late June until orders get into the country. The society has told its 9,000 members, who include radiographers, to prioritize urgent scans and try to find other suppliers.

A representative for GE Healthcare said the firm was “working around the clock to expand capacity” of the imaging chemical.

Luxury Stereos

Bang & Olufsen, the maker of luxury stereos and TV sets, this week cut its financial outlook due to the developments in China. The Danish company, which sells speakers costing as much as $110,000 a pair, said the lockdowns aren't just hurting local sales, but are also spilling into markets outside of China as restricted access to warehouses causes a string of logistical problems.

“The lockdowns have been more extensive than we anticipated, and it is not just affecting sales in China, but also the global availability of products,” Chief Executive Officer Kristian Tear said.

Automakers

A slew of carmakers from Volkswagen AG to Toyota Motor Corp. have started to resume production at factories in Shanghai and the industrial province of Jilin, though logistics issues continue.

Tesla Inc.'s plant in Shanghai has been plagued by disruptions, closing down for three weeks last month. It started up again in late April under a so-called closed loop system in which workers live on site and are tested regularly. But with Shanghai largely remaining in lockdown, there are still challenges for the delivery of supplies and materials.

The factory, which typically shipped around 60,000 cars a month, delivered only 1,512 vehicles out of Shanghai last month.

Toyota, meanwhile, is wrestling with an “unprecedented” rise in costs for logistics and raw materials, causing it to forecast a 20% decline in operating profit for the current fiscal year.

Carmakers on the other side of the world are also struggling to keep up with production as parts produced in China don't arrive. In Brazil, semiconductor shortages led factories to reduce output by at least 100,000 vehicles so far this year, according to the National Association of Automotive Vehicle Manufacturers.

In March, IHS Markit downgraded its forecast for global auto production in 2022 to factor in the impact from Russia's invasion of Ukraine, then lowered it further last month in response to the fallout from lockdowns in China, along with other mounting risks.

Catch all the Latest Tech News, Mobile News, Laptop News, Gaming news, Wearables News , How To News, also keep up with us on Whatsapp channel,Twitter, Facebook, Google News, and Instagram. For our latest videos, subscribe to our YouTube channel.